Yesterday, we were all invited to a morning at the Caterham Factory in Dartford. The primary focus of the day was on giving an insight to everyone as to how you go about setting up a Caterham for racing, rather than the road.

With Dartford only being 1.5 hours away, I decided it would be just about bearable to take the Caterham. Unfortunately, it was cold and a it brought all those memories flooding back of driving over to Keevil airfield in sub-zero temperatures. It didn’t help that my driver side mirror was pointing in exactly the wrong direction. This was bad enough while on the motorway, but getting to roundabouts in Dartford was not fun! I stopped in a lay-by to see whether I could adjust it and found fellow Academy racer Charlie, having just finished tucking into a bacon sandwich. He kindly offered the other two hands that you need to do anything on a Caterham, and the relief at being able to see behind was extreme!

Almost as much as the relief at holding onto a hot cup of tea after arriving at the factory! There are times when tea is the only medicine. After driving a Caterham on the M25 is one of those times.

After the usual natter with everyone, it was straight onto the setup talk by Simon Lambert. Ably assisted by glamorous assistant Mark Rider. There are others in Group 1 that couldn’t make the setup mornings, so I had agreed to take notes. Those notes are gathered here! It’s up to those competitors to work out whether I’m mean enough to throw in a curve ball or two into the mix :).

Ride Height

Description

Measured from the chassis rail to the floor just in front of the wishbone attachment point. This needs to be a minimum of 140mm for the Academy, although it is generally set at 145mm minimum as there is little benefit to running on the limit and this doesn’t allow for any suspension sag or tyre wear. It should be checked regularly. Track miles will wear out tyres and cause suspension to settle and sag a little.

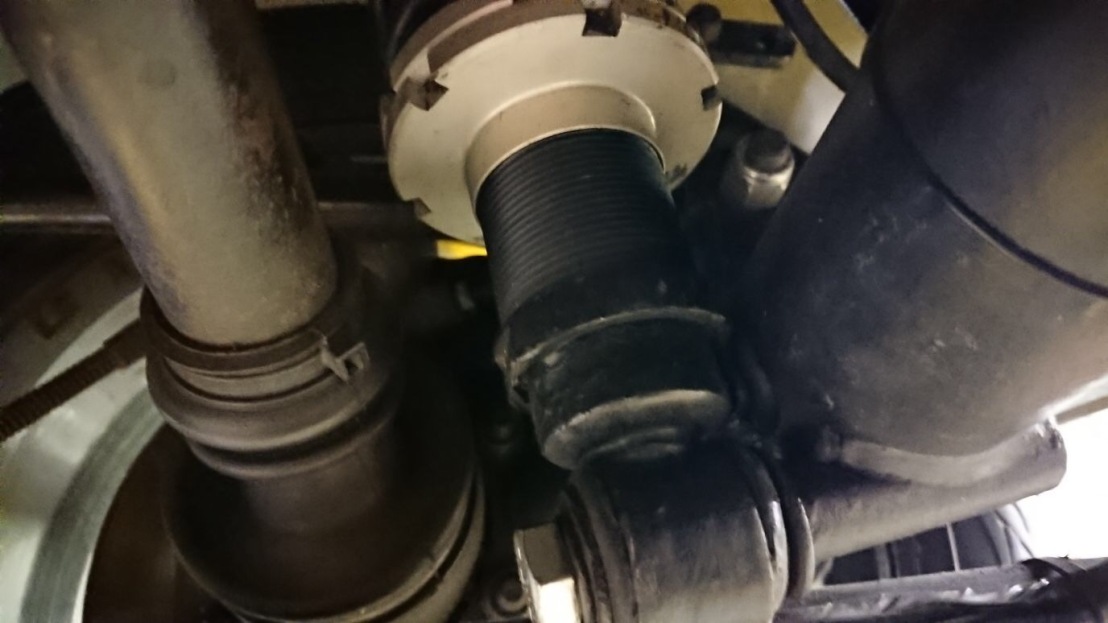

Adjustment

To raise the ride height, the upper platform at the bottom of the spring/damper unit should be screwed further up (compressing the spring more). To lower the ride height, the top platform should be loosened (decompressing the spring). Once set, the lower platform should be tightened up to lock them in place.

Benefit

Lowered centre of gravity of the car. This aids in all cornering, braking and accelerating.

Drawback

Little drawback other than grounding out or sailing too close to the wind with the regulations.

Camber

Description

Camber is the angle off vertical that the tyre leans sideways. It can be positive, where the tyre leans outwards, or negative, where the tyre leans inwards. You will only ever want negative camber. The regulations allow for 3 degrees negative camber at the front.

Adjustment

Normally, this is set at 2-2.5 degrees for Academy cars. Front camber is adjusted by releasing the top wishbone from the upright. The ball joint assembly is on a thread and ‘tightening’ the ball joint onto the wishbone will increase negative camber and ‘loosening’ the ball joint will decrease the negative camber. Rear camber is possible to achieve with metal shim inserts. The De-Dion has in built camber and for the Academy, it is rare to add any different setting as this reduces traction under acceleration.

Benefit

Adding negative camber allows tyre to sit flat on the road when leaning over under cornering load, therefore increasing tyre contact patch and so, grip under cornering.

Drawback

In a straight line there is a reduced contact patch on the tarmac and therefore less grip available to accelerating and braking.

Caster

Description

Caster is the angle around which the front tyres pivot when being turned. (The front wheel of a bike has lots of caster).

Adjustment

Front caster is adjusted using the lower wishbone, by using washers to push the attachment points forward or backward. Factory set is even with two washers either side of the attachment points. It can be moved forward or backward where all 4 washers are one side of the attachment points.

Rear caster is not relevant as the tyres do not turn.

Benefit

When the wheel turns, the caster adds additional camber. It is a way of getting more camber at the front of the car without breaking regulations. Most race engineers will want to set large amounts of caster.

Drawback

The trade off is heavy steering, making it harder to finesse the car and the car is less sensitive at turn-in. Driving style will determine whether these drawbacks are costing more time the the additional camber offers in grip.

Toe

Description

Toe is the angle that the wheels point away from parallel to each other. Where the front of the tyre is closer to the car than the back of the car, that is toe in. Where the front of the tyre is further away from the car than the back, that is toe out. Toe out is set for Caterham’s as this makes the car eager to turn.

Adjustment

Caterham’s are generally set with a toe out maximum in the region of 1.5 degrees per side at the front. You adjust the toe of the front tyres by turning the steering pushrods at either side of the car. This adjustment can also be used to centre a steering wheel that is slightly off centre.

In order to measure the toe, you need to set up axle stands around the car with pieces of wood or similar across the front. Tie string around the wood so that it goes from front to back parallel to the side of the car. (The exact dimensions of the ‘box’ you create around the car doesn’t matter.) You then position the string box so that the centre of each wheel is exactly the same distance from the string. You can then measure the distance from the front and rear of each tyre out to the string and the difference between the measurements is your toe.

Benefit

The car is eager to turn into corners. It wants to be going around bends and so makes turn in more responsive and positive.

Drawback

The car is more unstable in a straight line and will tend to move about. The tyres pointing away from straight ahead also causes drag in a straight line on the tyre as it slips sideways slightly.

Rake

Description

This is the amount that the rear of the car is set higher than the front of the car. Rake pushes more (raised rake) or less (lowered rake) weight onto the front of the car and therefore adds/reduces front grip. Lower rake lessens oversteer and increases understeer. Increased rake increase oversteer and reduces understeer.

Adjustment

Normally, this is set between 10-15mm higher than the front ride height. It is adjusted by raising / lowering the top platform of the rear dampers. Loosen off the lower platform, turn the top platform to adjust and then tighten the lower platform again once complete.

Benefit / Drawback

It’s more a case of driver preference and track requirements rather than benefits/drawbacks. It is a good way of adjusting the amount of oversteer in the car.

Flat Floor Setup

This doesn’t refer to the car sitting flat relative to the floor, it relates to the setup being carried out on a perfectly flat floor. For this reason, carrying out the adjustments for a flat floor is generally beyond the scope of an amateur builder.

As the car sits on scales on the flat floor, the weight that the car is putting down at each corner can be measured. The weights can be adjusted by raising or lowering the damper platforms.

In Caterham’s it is important to have the weight balance even across the front of the car to ensure maximum stability in braking.

Repeat Process

As each suspension component works in conjunction with all others, changing one will affect the others. Generally speaking, the setup and flat floor process is then carried out again until such time a geometry and weights are as good as they can be.

Front Anti-Roll Bar

Another element of the suspension that Academy cars have an option over is the front anti-roll bar. This bar dictates how much the car is able to lean over in corners. Academy cars are only fitted with a front bar and there are only 2 options. An orange bar, that the car is supplied with, and a red bar, that you can buy.

Theoretically, a softer anti-roll bar should be quicker however, a harder anti-roll bar gives a far better feel to the car and therefore many opt to use the stiffer bar. However, in the wet, the orange bar would be preferable as you generally want to increase grip as much as possible in the wet.

Sourced from Caterhamparts and professionally fitted by Ratrace Motorsport.

Sourced from Caterhamparts and professionally fitted by Ratrace Motorsport.